Bimetallic Bushing

Product -Bimetallic Bushing

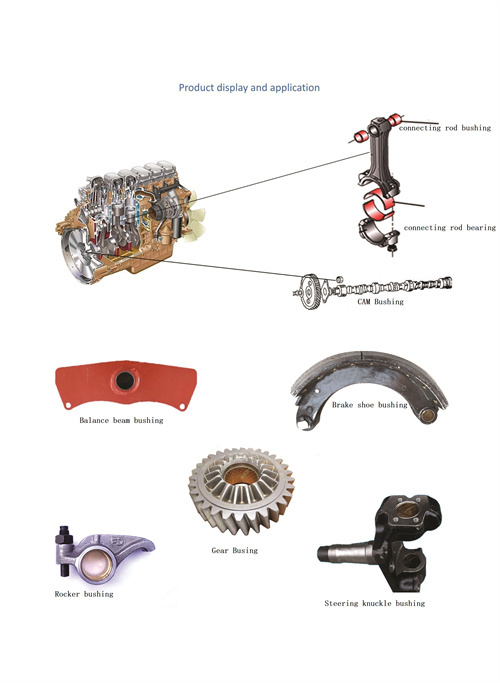

CuPb10Sn10 and CuSn6Zn6Pb3 are sintered on the surface of bimetal bushing

with low carbon steel plate as the matrix material.

The Working surface of the busing is designed with oil hole and oil groove to adapt to lubrication under the condition of oil. It can replace the copper busing in the general sliding position and is a kind of bushing with a wide range of USES, such as high load and low speed movement.

It is mainly used in internal combustion engine axle bush, connecting rod bushing, brake shoe bushing, balance bridge bushing of heavy truck, etc.

Production Capability

1) The company main products are polymer composite materials, SF-1, SF-2, bimetal composite materials and internal combustion engine bearing, automotive bushing, mechanical bushing, bridge support side sliding plate products.

2)At present, the company have production processing and testing equipment more than 80 sets, with 6 automatic sintering line of composite materials, the annual capacity can reach 3000 tons; Bushing products are mainly automatic production equipment, such as automatic rounding machine, automatic shaping machine, etc., punching machine from 16 tons to 160 tons, can meet the needs of different orders, annual capacity of up to 15 million; Bridge support side sliding plate products are equipped with an automatic sintering surface, with an annual capacity of 300 tons, The main testing instruments in the laboratory are scanning electron microscope metallographic analyzer, hardness tester, thickness tester, etc., which can meet eh testing needs of products and guarantee the quality of products.

The company has passed the IATF 16949 quality management system certification, always adhere to the “innovation and enterprising, quality win, meet customer requirements, exceed customer expectations “as the policy, dedicated to provide customers with high quality products and services.