Stainless steel castings

Our products produced with high quality by using reliable material, new technology, superior machining equipments & strictly process control .

As one leading company in precision casting field,

–we manufacture with following materials: GB(CHINA),ASTM(U.S.),DIN(GERMANY),JIS(JAPAN) :

304.304l,316,316l,410,cf8.cf3,cf8m,1.4301,1,4303, .4308,1.4404,1.4408,1.4581,SCS13,SCS14,

SCS13A,SCS14A,WCB,C45,C20,C10,15Cr3,15CrNi6,16MnCr5,34CrMo4,42CrMo4,56NiCr,MoV7 monel ally, Hastelly alloy,A356 ,LM6,ADC12…

—Machined Castings weight : 0.003kg-35kg

Angle Tolerance :+/-1 degree

Special Tolerance “+/-1/2degree

Casting surface roughness:Ra3.2-Ra12.5

Equipments:

1) Machining Equpments: 60 sets Mazak CNC lathe, 6sets Machining center(4 axils),2 sets DMG milling centre;EDM machine tool;Automatic feader machine; Laser marking machine; CNC milling machine; Vertical miling machine; Single groove milling machine, Double-groove milling machine; Engine lathe; Centerless grinder dilling machine ;Sawing machine;

2) Inspection Equipments: Brown sharpe Vedio Measurement; Sepctromaxx; Pressure test equipmetns…

3) Cleaning Equipements: Automatic leaning machine; Ultrasonic cleaning line;

QC Gurantee

Quality control process by : ISO9001, ISO/TS16949 and TUV certified.

ln order to assure the inspeciton level,we have CMM、SPECTROMAXX,、Spectrograph 2D Vedio Measurement、roughmeter、altimeter、hardness-testing device Ect.

ourmeasuring devices and gauges are inspected by specializedoffice each week.

There are IPQc、Sequence inspectorand final inspection tocontrol the qulaity.

Our final dimension inspection are down by CMM, Measures &Gauges,etc on the Final Control Record Sheet.

We have pressure testing equipments to check all pressurerequired components one by one.

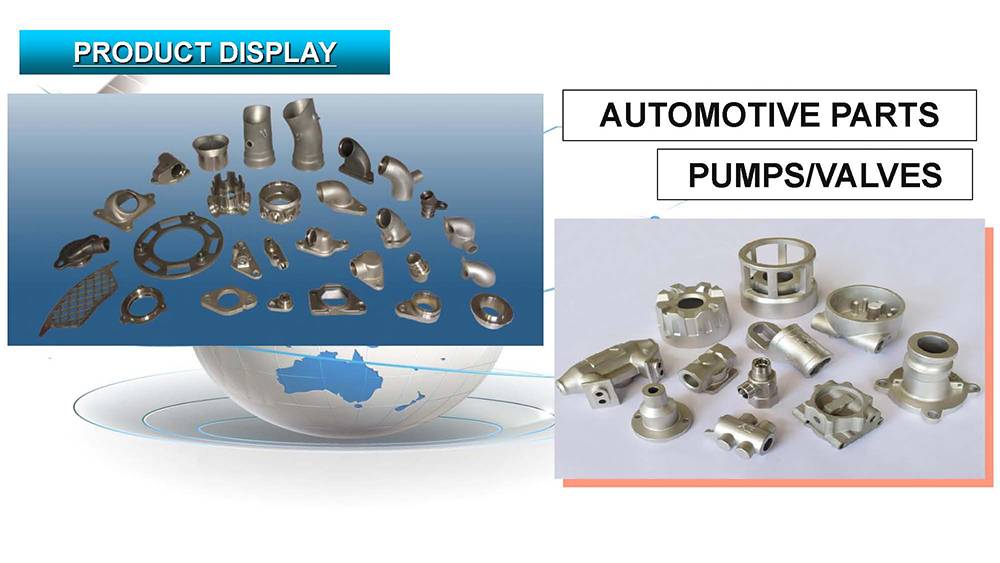

Main products:

1)Automobile parts;2)Pump Parts;3) Food machinery parts;4) Medical parts;5)Others

Materials: